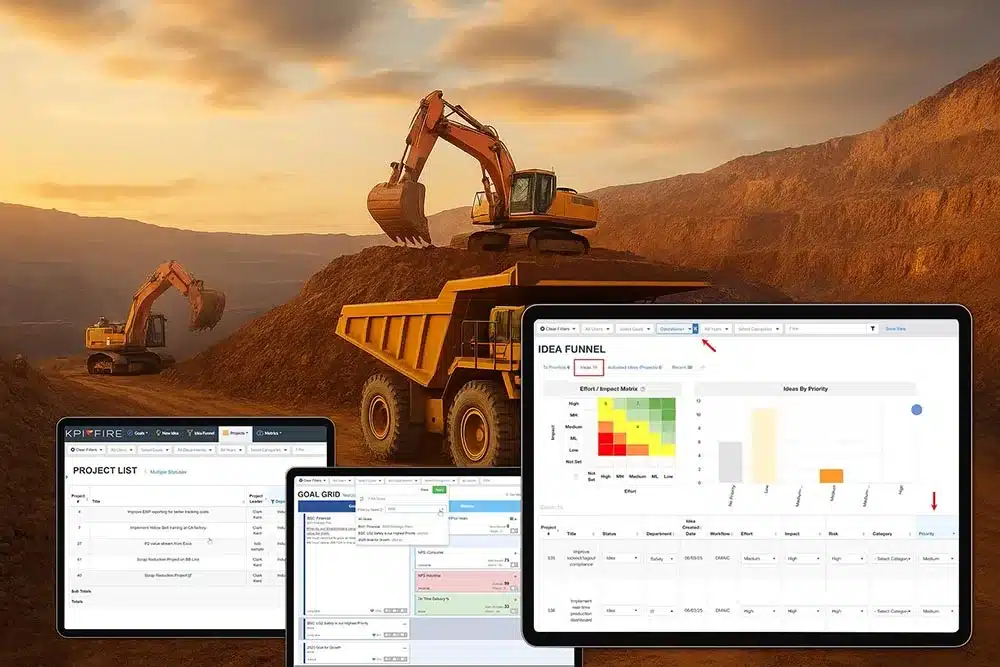

Business Improvement & Transformation Software for the Mining Industry

Unlock Higher Productivity in Mining with Continuous Improvement Software. KPI Fire helps mining companies align teams, track KPIs, and accelerate improvement projects. Empower operators, engineers, and site managers to identify opportunities, reduce downtime, and improve throughput. From pit to plant, KPI Fire connects strategy with frontline execution, making operations safer, more efficient, and more profitable.

Challenges Facing Mining Operations Today

- Rising operational costs and fluctuating commodity price

- Siloed improvement efforts and manual tracking

- Difficulty aligning strategic initiatives with frontline execution

- Safety, environmental, and compliance pressures

- Inconsistent performance across sites

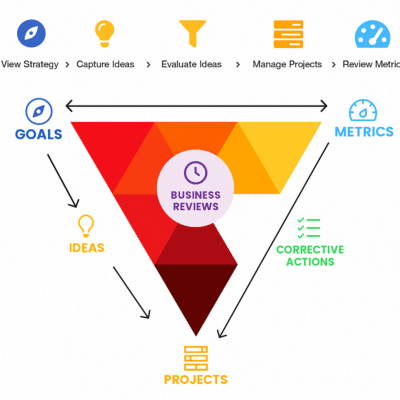

How KPI Fire Helps Mining Companies

- Transformational Change & Strategy Deployment: Cascade goals across regions and sites. Link Business Improvement projects with strategic objectives.

- Business Improvement Project Management: Manage Savings/Impact target vs actuals, Value Realization Reports, maintenance, and capital projects in one place

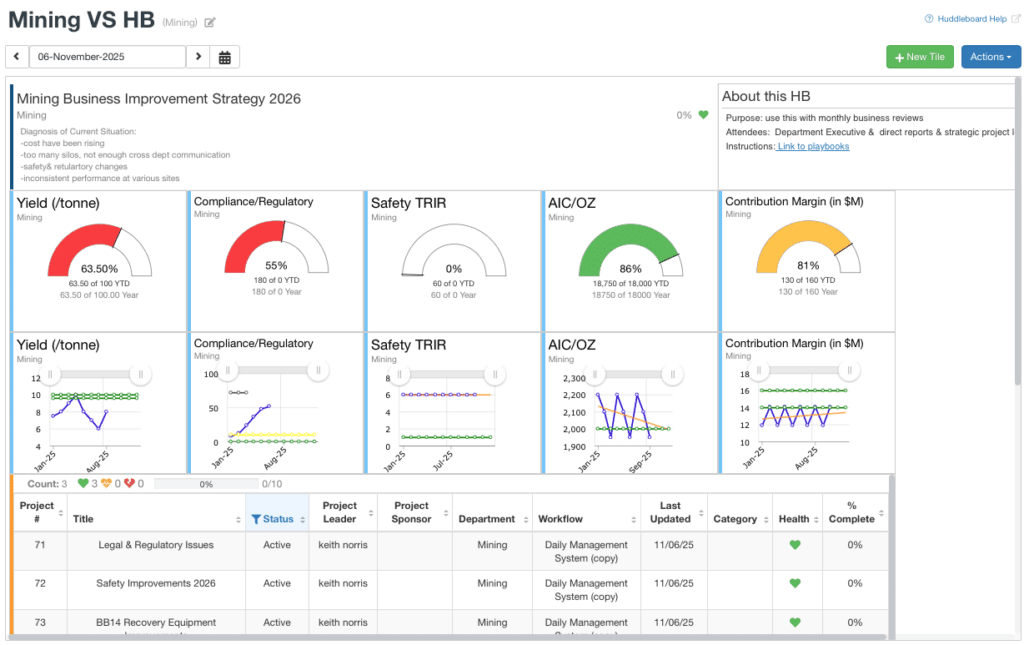

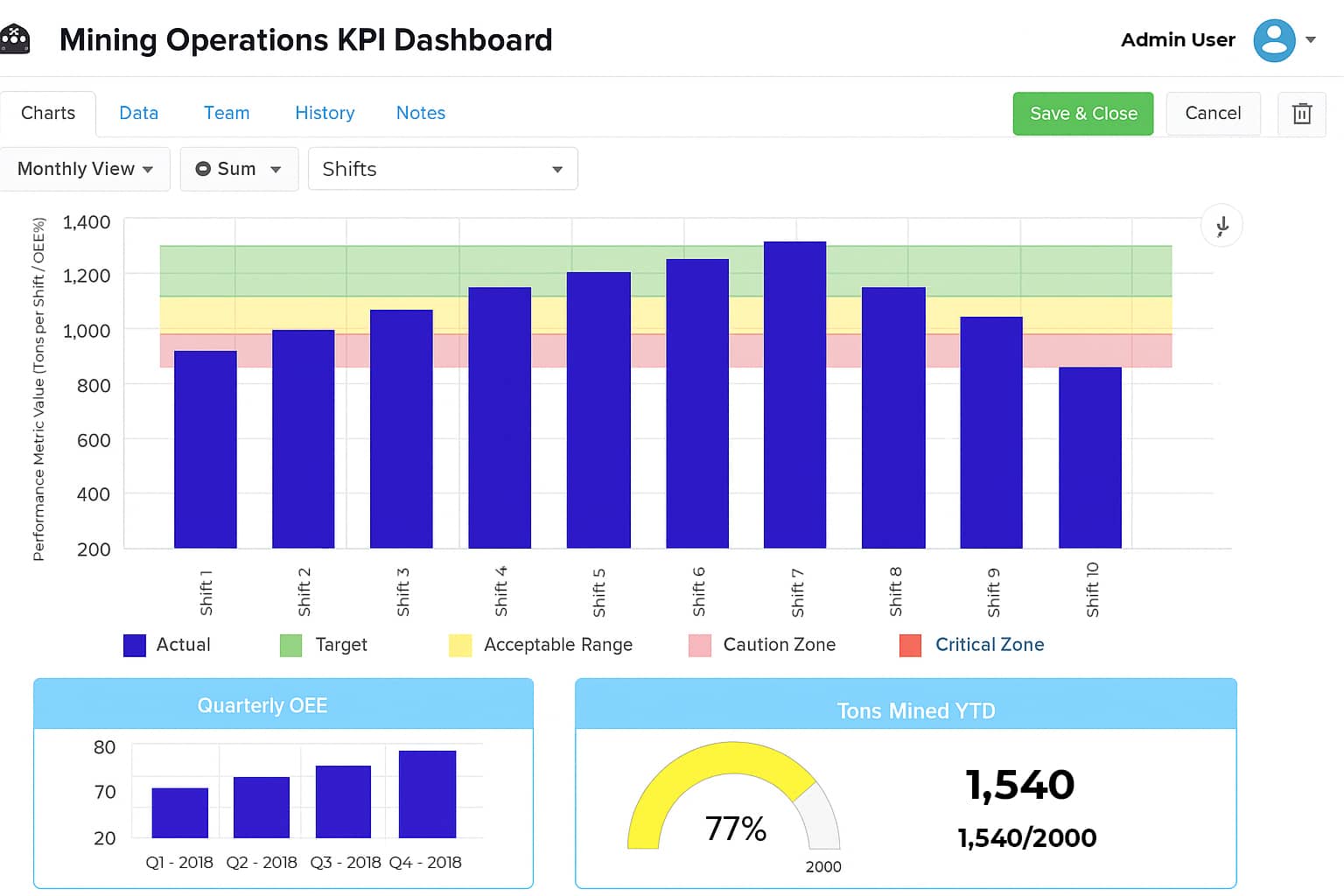

- Operating Performance: KPI Dashboards: Monitor OEE, Yield, Throughput, and Safety Metrics

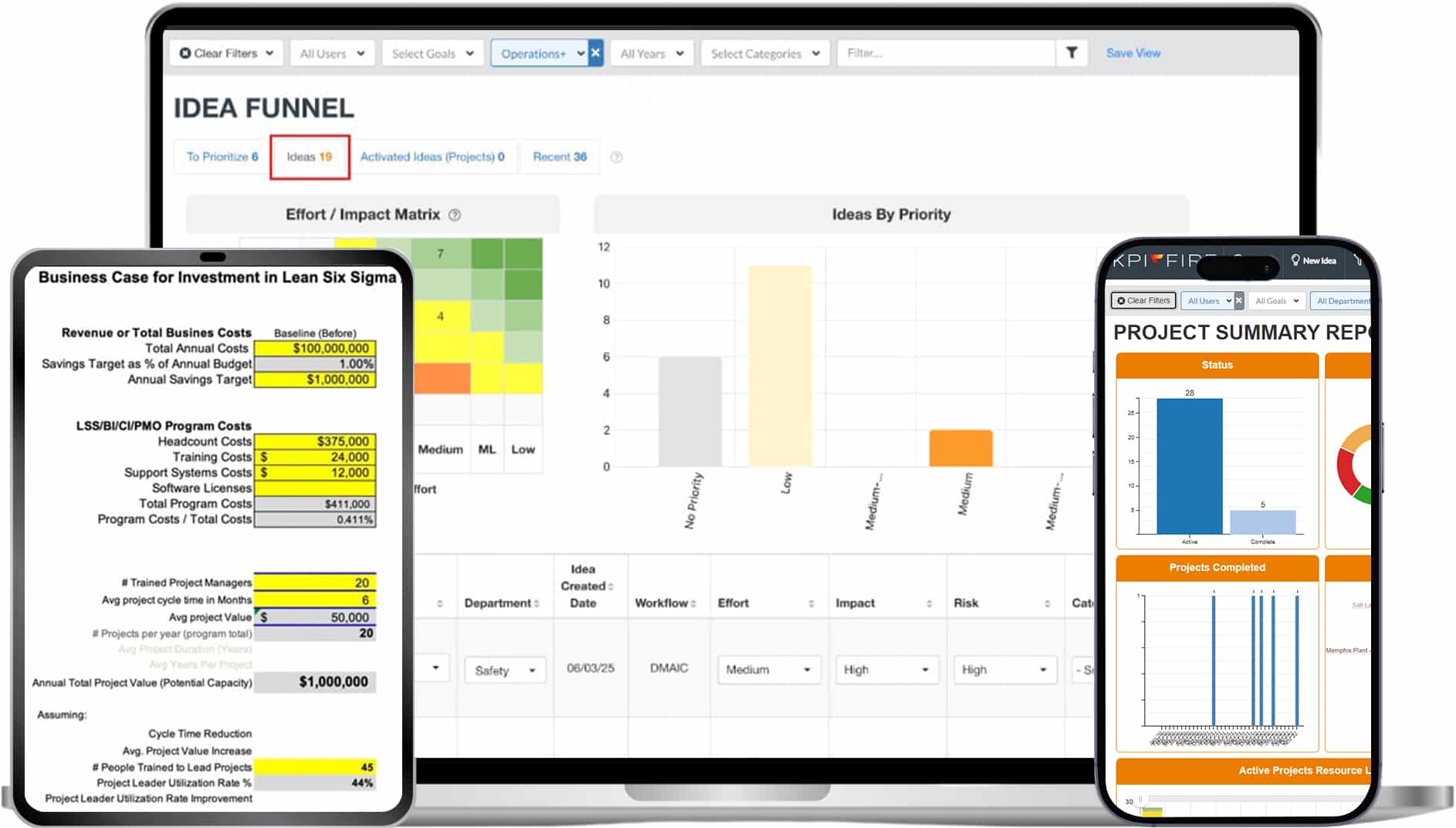

- Employee Engagement & Idea Capture: Idea Pipeline: Capture and evaluate frontline improvement ideas

- Audit and Compliance Tools: Track corrective actions from safety audits

Track What Matters Most in Mining

KPI Fire can be configured to track any relevant Key Performance Indicators. The KPIs most used in mining are:

- Cost Savings / Business Impact

- Utilization %

- Yield / Recovery Rate

- Throughput per Shift

- OEE (Overall Equipment Effectiveness)

- Downtime (by cause)

- Safety Incidents / TRIR

- Cost per Ton (All-In-Cost)

- Maintenance Compliance

- Employee Engagement in CI

- Water/Electricity Usage

- Carbon Reduction

- Environmental Impact

Real Results From Mining Team Like Yours

“Since implementing KPI Fire, our team has tracked over 110 Million in Business Improvement projects and aligned project work across 4 mine sites.”

— VP of Operations, Gold Fields

“After a recent merger our team evaluate all the system we were using. KPI Fire came out on top!.”

— VP Asset Optimization, Gold Fields

Works With Your Existing Mining Software Systems

Your internal IT department can rest assured that KPI Fire can make life easier.

- KPI Fire can connect with your existing systems for Single Sign on.

- Dashboard & Reporting tools like PowerBI, Excel, Tableau and more

- Push or Pull data with REST Apis

- Business Continuity procedures

- SOC2 Compliant

Use KPI Fire and Follow These Steps to Continuous Improvement

- Firstly, capture and prioritize improvement ideas with effort vs impact analysis.

- Next, manage projects with a standard approach (DMAIC, PDCA, 8D, other).

- Don’t forget to track and report project status and project benefits,

- And be sure to share best practices to become a learning organization.