How often does your team feel like it’s lost in a maze, fumbling in the dark for the finish line? Many teams, when tackling a new project or optimizing an existing process, struggle with a lack of clear direction. This often leads to wasted effort, missed opportunities, and ultimately, less-than-stellar results. But what if there was a simple, yet powerful, framework to illuminate the path and guide your team to success?

Enter Value Chain Analysis. This isn’t some complex academic theory; it’s a practical, straightforward tool that helps teams pinpoint exactly where value is being created and, perhaps more critically, where it’s being lost across all business activities. This article will demystify the Value Chain Analysis framework, providing clear examples of how your team can leverage it to dramatically improve efficiency and sharpen your competitive edge. Furthermore, we explore how tools like KPI Fire can seamlessly support this process, empowering your team to map, analyze, and continuously improve operations using real-time data and robust strategic alignment capabilities.

Main Take-Aways From This Article:

- Value Chain Analysis provides clear direction by pinpointing where value is created and lost, boosting efficiency and competitive edge.

- It’s broader than the supply chain, encompassing all activities that contribute to customer value and competitive advantage.

- This framework empowers teams to optimize costs, enhance collaboration, and differentiate themselves in the market.

- A simple 5-step process guides teams in mapping activities, analyzing value/cost, identifying opportunities, and creating action plans.

- Tools like KPI Fire are essential for practical application, offering real-time data, strategic alignment, and fostering continuous improvement.

What is a Value Chain, Anyway?

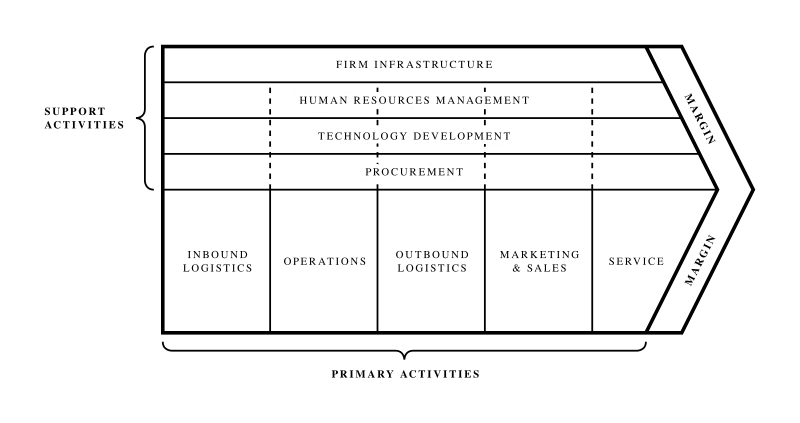

At its core, a Value Chain is a framework that dissects a company’s entire operation into a sequence of distinct activities, each playing a role in creating and delivering a product or service. Popularized by Michael Porter, this concept posits that competitive advantage doesn’t emerge from a company as a whole, but rather from how efficiently and effectively these individual activities are performed and how they interlink.

Imagine a manufacturing company: it’s not just “making widgets.” There are crucial steps like sourcing raw materials (inbound logistics), transforming them (operations), distributing finished goods (outbound logistics), and then marketing, selling, and servicing the product. These steps, along with supporting functions like HR and technology, collectively add value to the product or service in the customer’s eyes. The ultimate aim is to maximize this customer-perceived value while minimizing the associated costs, thereby boosting profit margins.

It’s crucial to understand that a Value Chain is broader than a Supply Chain. While a supply chain focuses purely on the operational flow of materials and information from suppliers to customers, the value chain encompasses this entire supply chain alongside all other activities—from research and development to customer service—that contribute to the creation of customer value and a company’s competitive edge. By breaking down the business into these interconnected components, teams gain a granular insight into precisely where value is generated, where inefficiencies might lurk, and where opportunities lie to differentiate themselves effectively from competitors.

Why Should Your Team Care About Value Chain Analysis?

Your team should care about Value Chain Analysis because it provides a critical framework for understanding how every activity within the organization contributes to delivering value to the customer and ultimately, to the company’s competitive advantage. This comprehensive view helps teams move beyond isolated tasks to see their role in the bigger picture, fostering a sense of purpose and shared responsibility. By meticulously examining each stage, from raw materials to final product and after-sales service, teams can identify areas for improvement and innovation.

- Optimizing Efficiency and Reducing Costs: Value Chain Analysis allows teams to pinpoint inefficiencies, bottlenecks, and redundant processes across all activities. By understanding the cost drivers at each stage, teams can identify opportunities to streamline workflows, eliminate waste, and allocate resources more effectively, leading to significant cost reductions and improved profitability.

- Enhancing Collaboration and Communication: When teams visualize how their work impacts upstream and downstream activities, it breaks down departmental silos and encourages cross-functional collaboration. This shared understanding promotes better communication, smoother handoffs, and a more unified approach towards achieving common organizational goals.

- Driving Competitive Advantage and Differentiation: Through Value Chain Analysis, teams can identify unique capabilities and activities that differentiate their company from competitors. This could involve superior quality, faster delivery, innovative product features, or exceptional customer service, enabling the organization to create a sustainable competitive edge in the market.

- Fostering Continuous Improvement and Innovation: The analytical process inherent in Value Chain Analysis encourages teams to continuously evaluate their processes and identify opportunities for improvement. This proactive approach not only leads to operational excellence but also stimulates innovation in products, services, and business models, ensuring the company remains agile and responsive to market demands.

Step-by-Step: Conducting a Simple Value Chain Analysis

Conducting a value chain analysis might sound complex, but for a team, it can be broken down into straightforward, actionable steps. The goal isn’t necessarily to become an expert economist, but to gain practical insights into how your team’s work contributes to overall value creation.

1. Identify Your Organization’s Primary and Support Activities

Start by listing out the core activities that directly create and deliver your product or service. These are the primary activities:

- Inbound Logistics: Receiving, storing, and distributing inputs (e.g., procurement of raw materials, inventory management).

- Operations: Transforming inputs into the final product or service (e.g., manufacturing, service delivery, packaging).

- Outbound Logistics: Collecting, storing, and distributing the product or service to customers (e.g., warehousing finished goods, order fulfillment, shipping).

- Marketing & Sales: Activities that encourage customers to purchase the product or service (e.g., advertising, sales force, pricing, channel management).

- Service: Activities that maintain and enhance the product’s value after sale (e.g., customer support, repairs, training).

Next, consider the support activities that underpin these primary functions:

- Firm Infrastructure: General management, planning, finance, accounting, legal.

- Human Resource Management: Recruiting, training, developing, and compensating personnel.

- Technology Development: R&D, product and process improvement, information systems.

- Procurement: Purchasing inputs or resources for all value chain activities.

For your team’s analysis, focus on the activities most relevant to your work and those directly impacting or being impacted by your team.

2. Map Your Team’s Specific Activities to the Value Chain

Now, take your team’s daily tasks, projects, and responsibilities and place them within the primary and support activities identified above.

- Example for a Software Development Team:

- Inbound Logistics: Reviewing requirements from product management.

- Operations: Coding, testing, bug fixing, deploying software.

- Outbound Logistics: Releasing new features to users (if applicable to their direct role).

- Marketing & Sales: Providing technical insights for sales demos (if applicable).

- Service: Responding to customer bug reports, providing technical support to customer service.

- Technology Development: Researching new technologies, improving development processes.

- Human Resources: Participating in hiring new engineers.

Be as specific as possible. This mapping helps everyone see how their work connects to the broader organizational functions.

3. Analyze the Value and Cost of Each Activity

This is where the “value” in value chain analysis comes in. For each activity your team performs or interacts with:

- Assess Value Contribution: How does this activity add value for the customer? Does it improve quality, reduce lead time, enhance features, or lower costs? Brainstorm with your team.

- Identify Cost Drivers: What are the main costs associated with this activity? This could include labor time, software licenses, equipment, training, etc. You don’t need exact financial figures, but a qualitative understanding of where resources are consumed.

- Look for Linkages: How do activities connect? Does an improvement in “Technology Development” (e.g., better development tools) reduce costs or increase value in “Operations” (e.g., faster coding)? Does poor “Inbound Logistics” (e.g., delayed requirements) negatively impact “Operations”?

Focus on activities where your team has direct influence or significant interaction.

4. Identify Opportunities for Improvement and Differentiation

With the mapping and analysis complete, start looking for actionable insights:

- Cost Reduction Opportunities: Are there activities where costs are high but value contribution is low? Can processes be streamlined, automated, or outsourced without sacrificing value?

- Value Enhancement Opportunities: Can your team’s activities be modified to add even more value for the customer? Can quality be improved, features enhanced, or service made more responsive?

- Bottlenecks and Inefficiencies: Where are things slowing down or breaking down? Are there poor handoffs between your team and others?

- Sources of Differentiation: What does your team do particularly well that contributes to a unique customer experience or competitive advantage? How can you amplify this?

- Innovation Potential: Are there entirely new ways your team could approach an activity to create significant new value or reduce costs drastically?

Encourage open discussion and brainstorming within your team.

5. Prioritize and Develop Action Plans

You’ll likely uncover many potential improvements. It’s crucial to prioritize based on impact and feasibility.

- High Impact, Low Effort: Tackle these quick wins first.

- High Impact, High Effort: Develop a plan with clear steps, resources, and timelines.

- Low Impact, High Effort: Reconsider these, or defer them.

For each prioritized opportunity, create a simple action plan:

- What needs to be done?

- Who is responsible?

- When will it be completed?

- How will success be measured?

By following these steps, your team can conduct a valuable, simple value chain analysis that empowers them to understand their strategic importance, identify areas for improvement, and actively contribute to the organization’s success.

Igniting Your Value Chain Analysis with KPI Fire

Understanding your value chain is one thing; actively managing and improving it is another. This is where a robust tool like KPI Fire becomes invaluable, acting as the catalyst that ignites your Value Chain Analysis from a theoretical exercise into a dynamic, actionable process. KPI Fire is designed to bridge the gap between identifying opportunities and executing tangible improvements, empowering your team to not only see their value chain clearly but also to optimize it continuously.

Mapping Your Value Chain with Precision

Before you can analyze, you need to visualize. KPI Fire provides intuitive features that allow your team to meticulously map out every activity within your value chain, whether primary or support. You can define each step, assign ownership, and outline the inputs and outputs, creating a comprehensive, shared understanding of your operational flow. This visual representation ensures that all team members, regardless of their role, can see how their individual contributions fit into the larger value creation process, eliminating ambiguity and fostering a unified perspective.

Fueling Analysis with Real-time Data

The true power of Value Chain Analysis lies in data-driven insights. KPI Fire integrates real-time data tracking, allowing you to monitor KPIs for each activity in your value chain. This means you can move beyond assumptions and gain concrete understanding of:

- Cost Drivers: Identify exactly where expenses are accumulating within each activity.

- Efficiency Metrics: Track cycle times, throughput, and resource utilization to spot bottlenecks and inefficiencies.

- Value Contribution: Quantify the impact of each activity on customer value and overall profitability.

With this immediate access to performance data, your team can quickly identify underperforming areas, validate assumptions, and prioritize improvement efforts based on hard facts, rather than guesswork.

Driving Improvement Through Strategic Alignment

Analysis without action is just information. KPI Fire excels at translating insights from your value chain analysis into actionable improvements. It allows you to:

- Set Clear Objectives: Define specific, measurable goals for optimizing each value chain activity.

- Align Initiatives: Link improvement projects directly to your strategic objectives, ensuring that every effort contributes to the overarching business strategy.

- Track Progress: Monitor the performance of your improvement initiatives against set KPIs, providing transparency and accountability across the team.

By providing a structured framework for improvement, KPI Fire ensures that your team’s efforts are always aligned with the strategic goals derived from your value chain analysis, maximizing impact and accelerating progress.

Fostering Continuous Optimization

Value Chain Analysis isn’t a one-time event; it’s an ongoing journey of continuous improvement. KPI Fire supports this iterative process by:

- Centralizing Information: Keeping all value chain maps, data, and improvement initiatives in one accessible platform.

- Facilitating Collaboration: Enabling seamless communication and collaboration among team members working on different parts of the value chain.

- Enabling Adaptability: Allowing for easy adjustments to your value chain map and KPIs as your business evolves or market conditions change.

Request a demo to discover how your team can establish a culture of continuous optimization – ensuring that your value chain remains lean, efficient, and highly competitive in the long run.